Precise pipeline asset optimisation

Amidst the global push to lower emissions, lower operational costs, and meet strict industry regulations, optimising your assets has never been more critical.

With Juno, Klarian offers a comprehensive solution to enhance operational efficiency. We develop proprietary algorithms to uncover valuable data slices, hidden insights and actionable intelligence, empowering you to manage your assets efficiently, safely, and profitably.

We take an agile approach, tailoring our solutions to your unique needs. By collaborating closely, we identify your challenges and develop data-driven solutions to boost operational efficiency, lower your emissions, and maximise your return on investment.

Juno Perform | pump optimisation.

Klarian's solutions

Collaborate with us to unlock the full potential of your pumps and compressors, driving greater efficiency and cost-effectiveness throughout your pipeline operations.

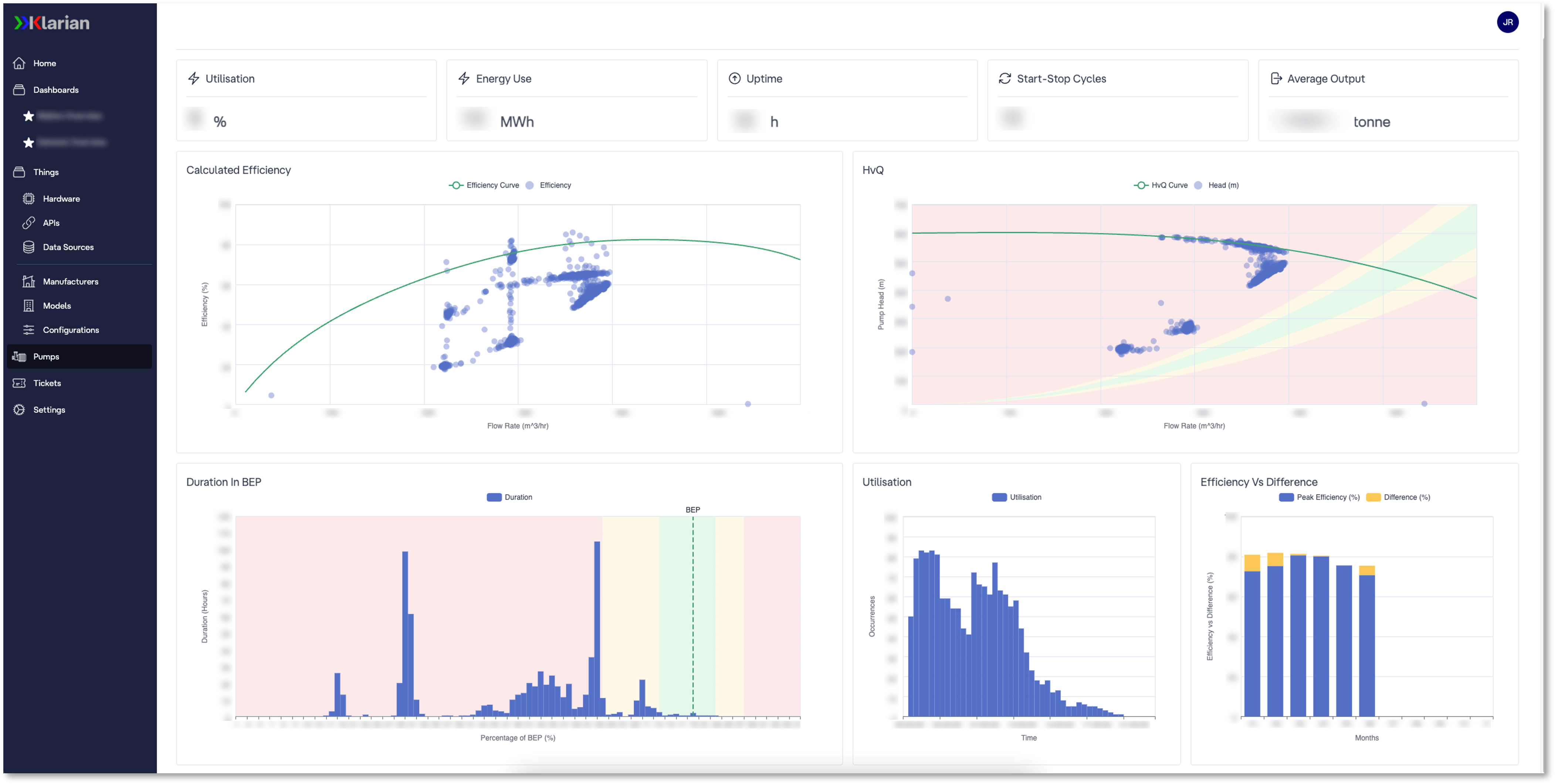

Pumps and compressors are energy intensive machines, making operational optimisation essential for reducing costs and energy usage. Many pipeline operators lack insight into individual compressors or pump station operating costs and power distribution throughout their systems. This data gap means you could be missing out on opportunities to optimise your network.

Juno offers a comprehensive solution by monitoring various parameters, including individual pump and compressor efficiency, power input to pump contribution ratios, and identifying error patterns compared to previous operations to inform maintenance decisions.

By giving you clarity on power usage and product flow volume, we can help you:

- Optimise your power input to product delivered ratio,

- Save energy,

- Enable effective cost management.

If you’re looking to learn more, check out the blog articles we’ve written on why you should prioritise pump and compressor efficiency and the role AI and data science can play.

Juno gives you confidence that your orifice plates are providing reliable measurements.

Orifice plate meters are a popular technology for fiscal metering, offering reliable and high-quality measurements over extended periods. If an orifice plate isn't installed properly following calibration, you run the risk of inaccurate flow measurements. These inaccuracies can have serious consequences, potentially leading to billing errors and economic losses or even jeopardising the safety of your pipeline system if you adjust pressure based on flawed measurements. This underscores the importance of continuous monitoring and anomaly detection of orifice plate performance within your local system.

Klarian offers a service whereby we take historical data from an orifice plate and build a profile of its successful operation. By comparing its performance before and after calibration, we spot anomalies early and ensure reliability. With a glance at an alert on your Juno Perform dashboard, you’ll quickly identify issues like reversed plate installation or other error patterns to ensure your measurements remain accurate and your operations run smoothly and safely.

Juno ensures you get early warnings of any faults by monitoring machine health. We help you extend maintenance time periods and maintain peak performance.

Behind every pipeline, a network of machines whirs away. Motors, bearings, pumps, and compressors all play a part in running your pipeline systems. Early identification of any faults is vital to avoid costly downtime. We deploy vibration, power usage, and power waveforms analysis for early insights into deteriorating machine health. By comparing vibration or power patterns against established norms, we quickly identify abnormal patterns. Through Juno Perform, you will receive early issue alerts, proactive maintenance cues, and continued confidence in the optimal function of your equipment.

Using our advanced analytics expertise, we can quickly build condition monitoring models. Our models work particularly well for rotating machinery like pumps. We can also deploy our edge computer to integrate data from your existing sensors and integrate them with any new sensors required for full coverage.

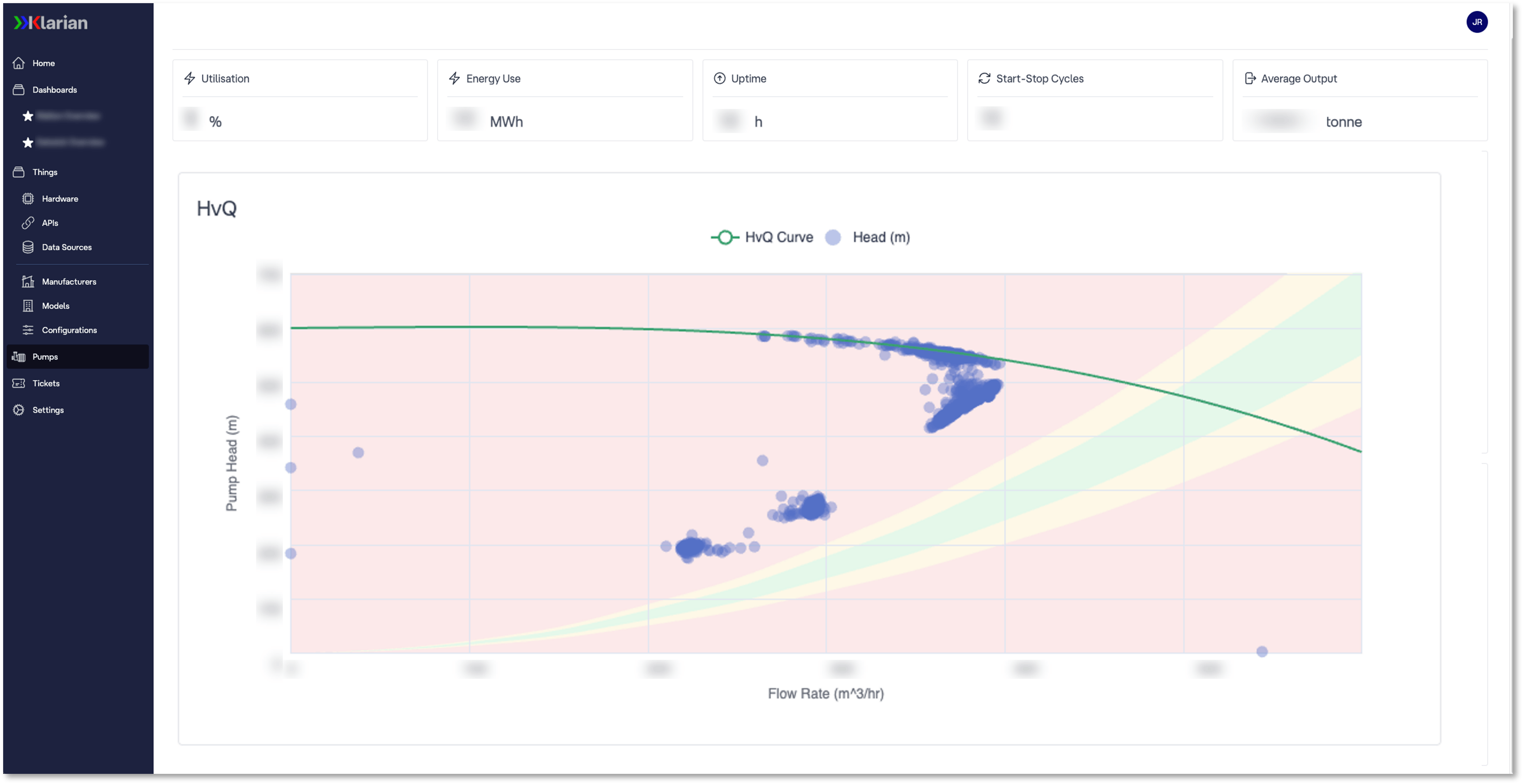

Digipipe | pump optimisation - HvQ.