Our successful first field trial

If you read our last blog article or have been following us on social media, you will know that we have conducted our first field trial of our end-to-end technology platform. Since mid-February 2022, we have been monitoring critical national infrastructure.

Field testing our solution is a crucial milestone towards our aim to optimise pipeline infrastructure for a more sustainable planet. The team has developed an agile and innovative solution that collects pipeline data and transforms it into performance clarity.

Overview of the trial

The field trial was performed on the Manchester Jet Line (MJL), a pipeline supplying aviation fuel to Manchester airport in the UK. The trial was conducted in partnership with Penspen, global energy consultants, who operate the MJL.

The field trial tested the whole breadth of our technology platform, from the field equipment to the front end.

A fully installed LIMPET on the Manchester Jet Line

Getting the trial up and running

Since the trial included deploying two of our prototype field equipment units, the LIMPETs (non-invasive, retrofit clamp-on sensor suites) needed to achieve ATEX certification before installation. ATEX is the European standard for verifying that equipment is intrinsically safe. Thanks to the hard work of the engineering team, the LIMPETs became ATEX certified in early 2022, and we started planning for the trip to Manchester for installation.

With ATEX achieved, our hardware engineers packed up the LIMPETs and embarked on the long drive to Manchester in mid-February. Once they had arrived, they installed two LIMPETs at two selected points along the MJL. With assistance from Penspen and the software team back in Exeter, the first LIMPET was up and running by midday on the very first day of the trial. The second LIMPET shortly followed, and we proceeded to monitor the pipeline. One of the advantageous of our Intelligent Pipelines solution is that it is retrofittable and non-invasive, so when our team were installing the LIMPETs no downtime of the pipe was required. The moment our system was live, it was monitoring the pipeline.

Dr Liam Trimby installing one of the LIMPETs onsite at the Manchester Jet Line

The trial's impact

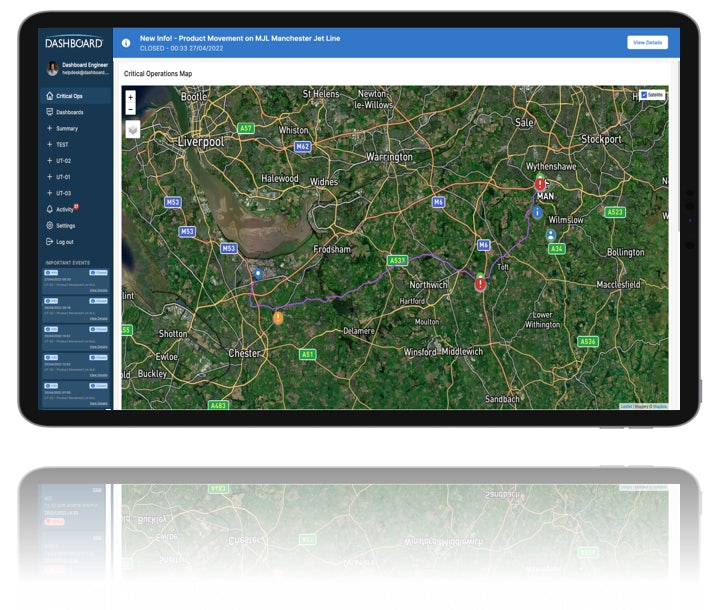

With pre-existing metered sources at the beginning and end of the MJL line indicating process volumes passing through, the addition of the LIMPETs at two points made real-time fuel flow insights available. We have enhanced clarity on current and historic flow profiles, allowing MJL engineers to see these insights visualised on our intuitive, user-friendly interface wherever they are.

The map view of the front end

The trial has helped improve operational efficiency by enabling MJL engineers to remotely monitor pipeline performance on the go.

Importance of the trial to the team

The trial has meant a great deal to the team who have worked hard to make it a reality. As well as delivering the trial, the team’s focus is already on how we can enhance our technology platform to provide the greatest value possible to our clients.

Here is what the trial has meant to a few members of our team:

- Ben Cleary, Head of Technology: "Our most recent trial deployment has been a huge success for the team. We now have a wealth of experience and insight which we can take forward to refine our product and platform to maximise value to our users."

- Darren Fellows, Principal Design Engineer: "For me, the trial has been a success. The installation went very smoothly for a first time ever install and we have learned a lot. We will use these lessons to continue developing our product.”

- Dr Liam Trimby, Instrumentation Scientist: "It was immensely satisfying seeing the sensors that I helped design and build installed and tracking real jet-fuel flow. The way everything came together was remarkably smooth. The low-level cloud integration even allowed me to continue monitoring and tweaking performance during the journey home."

- Kerenza Teague, Junior Front End Developer: "Seeing real pipeline data used in the software that we built was a huge moment for the team. We can now look to enhance and further develop our software so that customers get maximum value."

Dr Liam Trimby at the installation site next to the edge controller

Next steps

As the team have made clear, the next step is refining and enhancing our product to maximise the value that it delivers when optimising pipeline infrastructure for a more sustainable planet.

Continue following our blog and LinkedIn to stay up to date with our progress.